- Home /

- Application /

Metallurgy

Metallurgy is divided into ferrous and nonferrous metallurgy:

- Ferrous metallurgy includes production and dressing of ferrous metal ores (ferrous metal is iron, all other metals are nonferrous), ironmaking, steelmaking, ferroalloys making. Ferrous metallurgy also includes production of rolled ferrous materials, steel, iron articles and other articles made of ferrous materials.

- Nonferrous metallurgy includes production and dressing of nonferrous metal ores, production of nonferrous metals and their alloys.

Application of gas-analysis equipment in metallurgy depends on type of production, type of technological process and specific safety requirements, and is characterized by a great variety.

Some standard tasks of gas analysis are the following:

- continuous monitoring of purity of oxygen (0—2 vol. % H2 in O2) and hydrogen (0—1 vol. % O2 in H2) – water decomposition products with the use of electrolysis method at electrolysis station;

- continuous monitoring of purity of oxygen (98—100 vol. % O2) and nitrogen (trace concentrations of oxygen in N2) – air separation products at oxygen separation station;

- continuous monitoring of top smoke composition (contains Н2, СО2 and СО);

- continuous ecological monitoring of combustion gases resulting from blast-furnace gas afterburning with calculation of gross emissions. As a rule, measured combustion gases have the following composition: 3.5—4 vol. % О2, 25 vol. % СО2, up to 2.5 g/m3 СО, 20 mg/m3 SO2, 1000 mg/m3 NOx;

- continuous monitoring of oxygen concentration in coke oven gas after gas purification. О2 content in the composition must not exceed 1 vol. %. Standard composition of coke oven gas: 3 vol. % СО2, 6 vol. % СО, 26 vol. % СН4, 60 vol. % Н2, 2 vol. % ∑СН;

- continuous monitoring of oxygen concentration in ferroalloy gas. О2 content in the composition must not exceed 2 vol. %. Standard composition of ferroalloy gas: 10 vol. % СО2, up to 85 vol. % СО, up to 4 vol. % СН4, up to 8 vol. % Н2.

"Analitpribor" products used for solving the following standard tasks of gas analysis at metallurgy enterprises:

- continuous monitoring of purity of О2 and Н2 – gas analyzers ДАМ with power supply units БПС-21М3

- monitoring of trace concentrations of oxygen (nitrogen purity) – АНКАТ-500

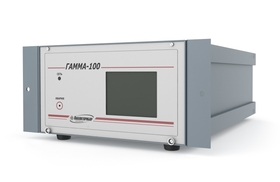

- monitoring of top smoke – set of gas-analysis equipment (КГО) using devices ГАММА-100 and sample preparation elements

- continuous ecological monitoring of combustion gases resulting from blast-furnace gas afterburning with calculation of gross emissions – set of gas-analysis equipment (КГО) using devices ГАММА-100 and sample preparation elements

- continuous monitoring of oxygen concentration in coke oven gas and in ferroalloy gas after gas purification – set of gas-analysis equipment (КГО) using devices ГАММА-100 a and sample preparation elements designed for installation in hazardous areas.